Top Choices For Barn Leveling Accessories And Tools

Find essential accessories and tools that help simplify barn leveling tasks, ensuring long-lasting stability and safety.

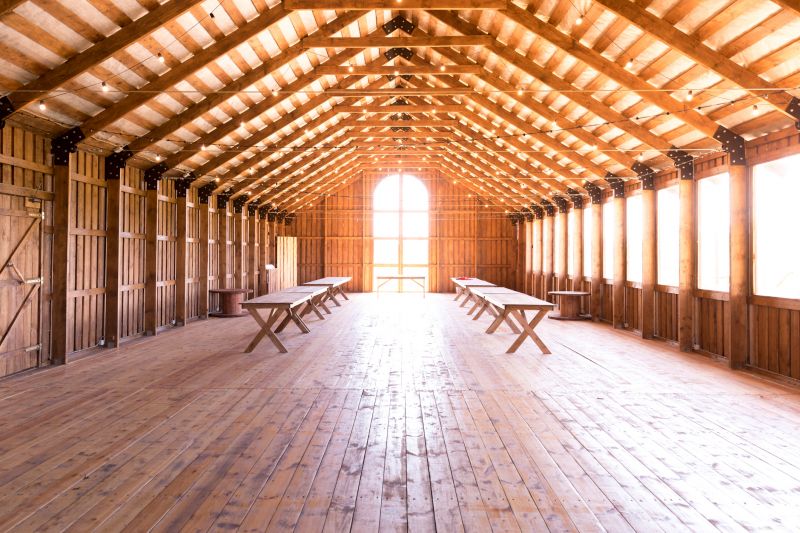

Maintaining a level barn floor is essential for the safety and comfort of both animals and handlers. Proper barn leveling helps prevent uneven wear on equipment, reduces the risk of injuries, and ensures efficient operations. There are numerous products available designed to assist in achieving and maintaining a flat, stable surface within barn structures. These tools and materials vary widely in their application, from small adjustments to large-scale leveling projects. Selecting the right products depends on the specific needs of the barn, including size, existing surface conditions, and the desired longevity of the fix.

Maintaining a level barn floor is essential for the safety and comfort of both animals and handlers. Proper barn leveling helps prevent uneven wear on equipment, reduces the risk of injuries, and ensures efficient operations. There are numerous products available designed to assist in achieving and maintaining a flat, stable surface within barn structures. These tools and materials vary widely in their application, from small adjustments to large-scale leveling projects. Selecting the right products depends on the specific needs of the barn, including size, existing surface conditions, and the desired longevity of the fix.

Top Overall Option

Adjustable Barn Leveling Kit

An adjustable barn leveling kit offers a versatile solution for maintaining a flat and stable barn floor. These kits typically include adjustable jacks, shims, and support beams that can be customized to fit different barn sizes and surface irregularities. They are designed for ease of installation and can be used for both minor adjustments and significant leveling projects, providing a reliable way to address uneven surfaces over time.

Types of Products For Barn Levelings

Shims and Spacers

Used for small adjustments to level uneven surfaces, these come in various materials and sizes to fit different needs.

Leveling Blocks

Stackable blocks that help raise low spots or create a level surface, often made from durable plastic or rubber.

Adjustable Jack Supports

Mechanical jacks that allow for precise height adjustments, suitable for larger or more complex leveling tasks.

Concrete Resurfacing Products

Materials designed to repair and smooth out existing concrete floors, providing a more even surface.

Polymer Floor Patches

Flexible patches used to fill cracks or holes, helping to create a smoother, more level surface.

Drainage Grates and Slopes

Products that help manage water runoff and prevent pooling, contributing to a more stable surface.

Vibratory Rollers

Heavy machinery used to compact soil or gravel layers, creating a solid foundation for barn floors.

Gravel and Base Materials

Layered materials that form a stable base for concrete or other flooring options.

Polyurethane Foam Fillers

Lightweight, quick-curing foam used to fill voids and level uneven areas beneath flooring surfaces.

Hydraulic Leveling Systems

Advanced systems utilizing hydraulics for large-scale and precise adjustments of barn floors.

Vibrating Plate Compactors

Tools used to compact soil or gravel layers, ensuring a stable base for flooring.

Concrete Curing and Sealing Products

Products that help protect freshly poured concrete and maintain a smooth, even surface.

Self-Leveling Underlayment

Materials that create a smooth, flat surface over uneven concrete or subflooring.

Sand and Gravel Mixes

Used to fill low spots and create a level base before final flooring installation.

Vibration Damping Mats

Mats designed to reduce vibrations and stabilize flooring surfaces, especially in high-traffic areas.

Popular Choices

Interlocking rubber mats provide a cushioned, level surface suitable for animal comfort and safety.

Ready-mix compounds used to fill and smooth out uneven concrete surfaces in barns.

Support beams that can be adjusted to correct surface dips and ensure stability.

Crushed gravel layers used as a foundational base for further flooring or surface improvements.

Durable coatings that help protect and level barn floors, providing a smooth finish.

Pads that help reduce impact and vibrations, improving floor stability and safety.

Chemical stabilizers used to improve soil strength before laying foundations or flooring.

Portable hydraulic jacks for lifting and leveling heavy sections of barn floors or supports.

Sealants that help protect floors from moisture infiltration, maintaining surface integrity.

Compact soil or gravel layers to create a firm base for barn flooring.

Materials designed for patching and smoothing concrete surfaces to improve flatness.

A quick-setting cement that can be poured over uneven surfaces to create a level finish.

Devices used to modify the height of support posts and beams for better floor alignment.

Heavy-duty rollers that compact base materials for a stable foundation.

Barn leveling often involves a combination of tools and materials that can address uneven surfaces, fill low spots, or raise sagging sections. For smaller adjustments, hand tools such as shims and leveling blocks are common. For larger or more complex projects, power tools and specialized machinery may be necessary. Durable, weather-resistant materials are especially important for outdoor or semi-outdoor barns, where exposure to the elements can accelerate wear and deterioration.

Proper planning and the right product choices can make the process more efficient and effective. It is important to consider the weight and type of loads the barn will carry, as well as the frequency of maintenance needed. Investing in quality products can help ensure long-term stability and safety, reducing the need for frequent repairs. Whether you are doing a minor correction or a comprehensive leveling overhaul, understanding the product options available can help you select the best tools for your specific barn environment.

Key Buying Considerations

- Assess the extent of unevenness or damage to determine the appropriate product type.

- Consider the size and layout of the barn to select suitable tools and materials.

- Evaluate whether surface repairs are temporary or require long-term solutions.

- Check the durability and weather resistance of materials, especially for outdoor barns.

- Determine if professional installation or DIY methods are preferred for your project.

- Review the load-bearing requirements to ensure the selected products can handle the weight.

- Consider the compatibility of materials with existing flooring or foundation components.

- Factor in the frequency of maintenance and future adjustments needed.

- Select products that are easy to use and allow for precise adjustments.

- Review safety features and handling instructions for power tools and machinery.

- Estimate the overall project budget, including labor, materials, and equipment rentals.

- Think about water drainage and moisture management to prevent future issues.

- Prioritize products with good reviews for reliability and ease of use.

- Identify whether surface preparation (cleaning, drying) is necessary before application.

- Ensure availability of replacement parts or accessories if needed for ongoing maintenance.